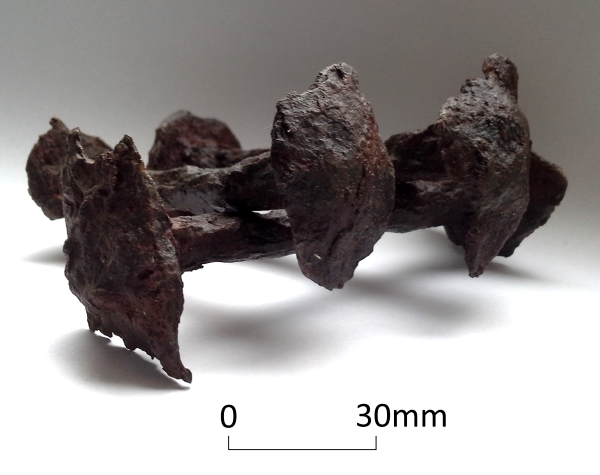

The image for Day 140 of VM_365 is of a group of iron clench bolts, found in the excavation of an Anglo Saxon grave near Thorne Farm, Minster between 1983 and 1984. Each bolt has a domed head at one end and at the other end the shank passes through a flat lozenge shaped plate, called a rove. The plate held in place by bending and flattening the shank to cover the hole, preventing it from sliding off the shank. Bolts of this type were used as fixings in early planked ships of clinker construction where the covering boards overlap. Perhaps the most important and well known archaeological discovery of an Anglo-Saxon ship built in this way is the Sutton Hoo ship. The bolt and rove act as a clamping rivet, holding two overlapping planks tightly between the domed head and the tightly clamped plate. Eighteen bolts of this type were distributed throughout the fill of the grave and in the soil in the wider area around the grave.

The gaps between the bolt heads and the roves from the grave measure approximately 60mm and appear to have been used to fasten wooden planks together in some form of structure that was used to cover the grave, impressions of wood were visible in the corroding iron of the bolts.

It is difficult to reconstruct what form the grave covering took, whatever covered the grave was bigger than the cut containing the burial. It has been suggested that because these bolts were commonly used in shipbuilding, the covering structure could possibly have been a small wooden boat, or a piece of a larger boat. Another possibility is that a sort of sea-chest, which a sailor may have kept his personal equipment in, might have been constructed with clench bolts in the same way as ships were. Perhaps old sailors were finally laid to rest with under the weathered and worn fragments of shipwrecks, small boats and even the sea-chests that would have formed such an important part of their lives.

Reference

Perkins, D. R. J. 1985. TheMonkton Gas Pipeline: Phases III and IV, 1983-84. Archaeologia Cantiana Volume CII, 43-69.

Day 139’s VM_365 image shows a Roman lock fastener from the villa at Minster.

Day 139’s VM_365 image shows a Roman lock fastener from the villa at Minster.